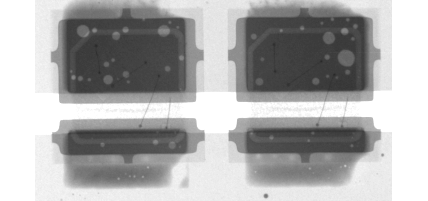

TruView™ X-ray systems have been specially designed to inspect and measure the voids in LED assemblies. These measurements are paramount to build reliable products, since voids in the solder between the LED and the substrate cause the device to run warmer. Because the lifespan of an LED rapidly decreases as its operational temperature increases, voiding in the solder layer is directly associated with the lifespan and light profile of your LED assembly.

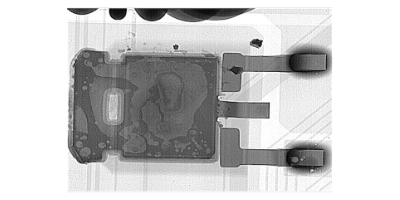

TruView™ X-ray Systems have been specially designed to inspect and measure the voids in power device assemblies. These measurements are paramount to build reliable products, since voids in the solder between the power device and the substrate cause the device to run warmer. Since the lifespan of a semiconductor rapidly decreases as its operational temperature increases, voiding in the solder layer is directly associated with the lifespan of your power device assembly.