TruView™ X-ray inspection systems can track the location of a single or multiple conductors and jackets in real time. The relative (or absolute) thickness results can be flagged to the operator or automatically used to correct the extruder.

As with everything else, connectors and their pins are getting smaller and smaller. Smaller means more fragile. After assembly, confirming the integrity of the wire and pin is an important step to the manufacturing process.

Missing a crimp leads to a broken connection, which is typically caught in in-circuit testing. However, over crimping often isn’t and these can lead to intermittent or latent failures in the field.

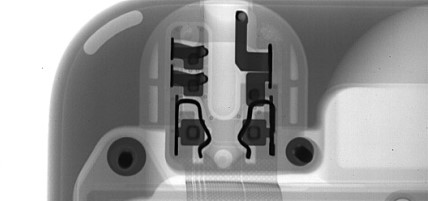

The mechanical connection is just as important as the electrical connection when talking about frequently used ports on a consumer device. Cracks at the anchor points will eventually lead to broken signals. A device that can’t charge isn’t worth anything to your customer.

Crackling music can be infuriating enough to throw your phone on the ground. Avoid that by verifying the integrity of the audio jack using X-ray inspection.